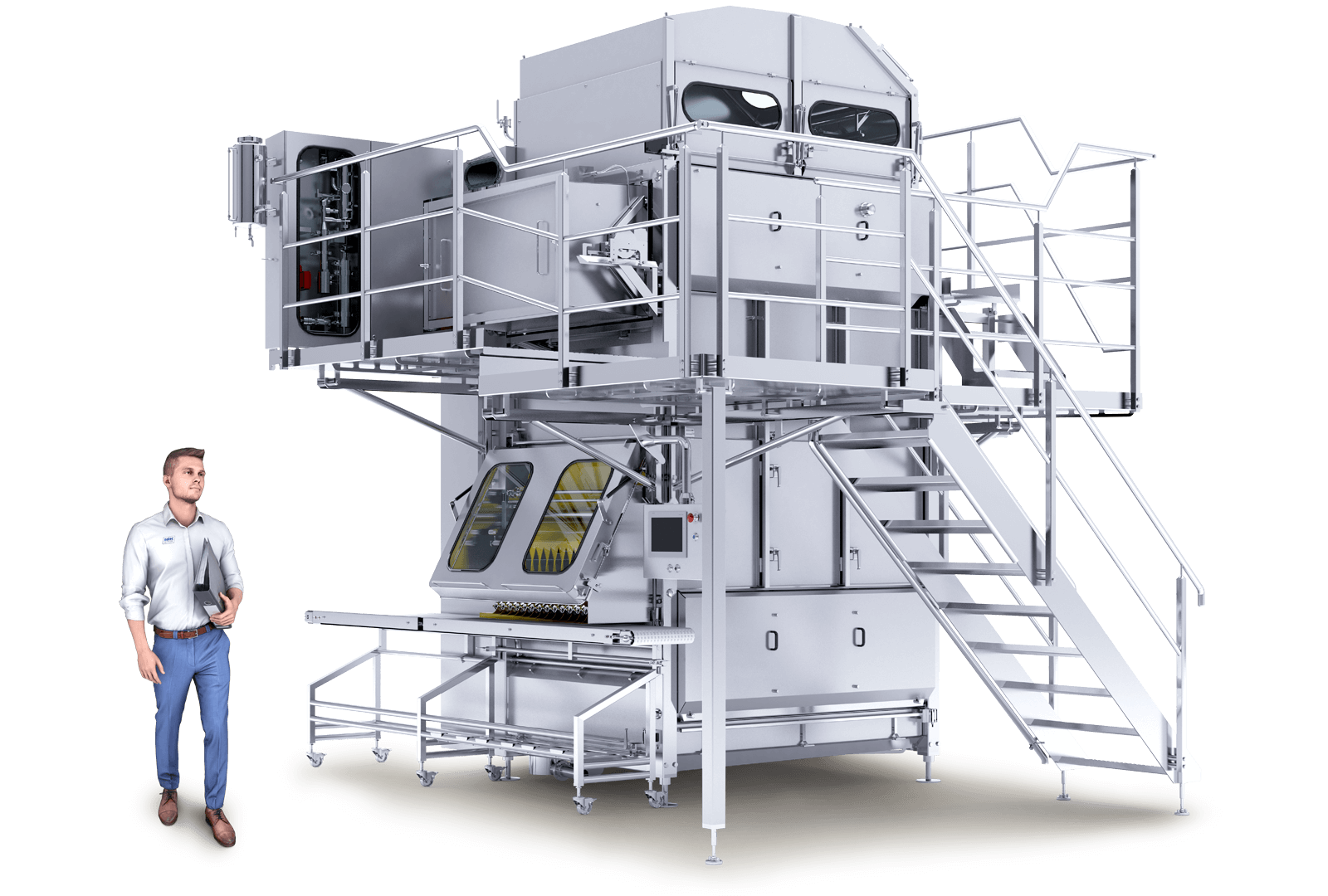

Benefits

No recontamination

- Laminar flow system to avoid recontamination

Clean-In-Place

-

The system is fully CIP able including the laminar flow part

Full control

-

The central control surveillance system makes a comfortable and trouble-free production possible

Highest flexibility

-

Different add-ons make it highly flexible for any application made of processed cheese, analogue or hybrid cheese