Ideal standards

for your baby

The production of baby food requires the highest standards in quality and safety. We offer an unprecedented level of control for producing an entire spectrum from chunky to smooth baby foods and easy-to-chew foods. Extremely short processing time maintain the freshness of ingredients and nutrients. For your requirements we ensure highest hygienical standards, bacteriological safety and long shelf life thanks to pasteurisation and sterilisation.

Which baby food processing equipment?

Natec is famous for building systems based around direct steam injection cookers. Steam is the fastest way to cook, and it's healthy. Being fast, steam allows us to cook big volumes rapidly, and it doesn't burn out the nutrients and colours that other processes do. Our largest RotaTherm® can continuously cook up to 17,000kg (37,500lb) of baby food per hour, for 156 hours between fast CIP cleans. Our MicraTherm cooks batches at around 8kg (16lb) per hour, and we have batch and continuous cookers of all sizes in between.

Natec is famous for building systems based around direct steam injection cookers. Steam is the fastest way to cook, and it's healthy. Being fast, steam allows us to cook big volumes rapidly, and it doesn't burn out the nutrients and colours that other processes do. Our largest RotaTherm® can continuously cook up to 17,000kg (37,500lb) of baby food per hour, for 156 hours between fast CIP cleans. Our MicraTherm cooks batches at around 8kg (16lb) per hour, and we have batch and continuous cookers of all sizes in between.

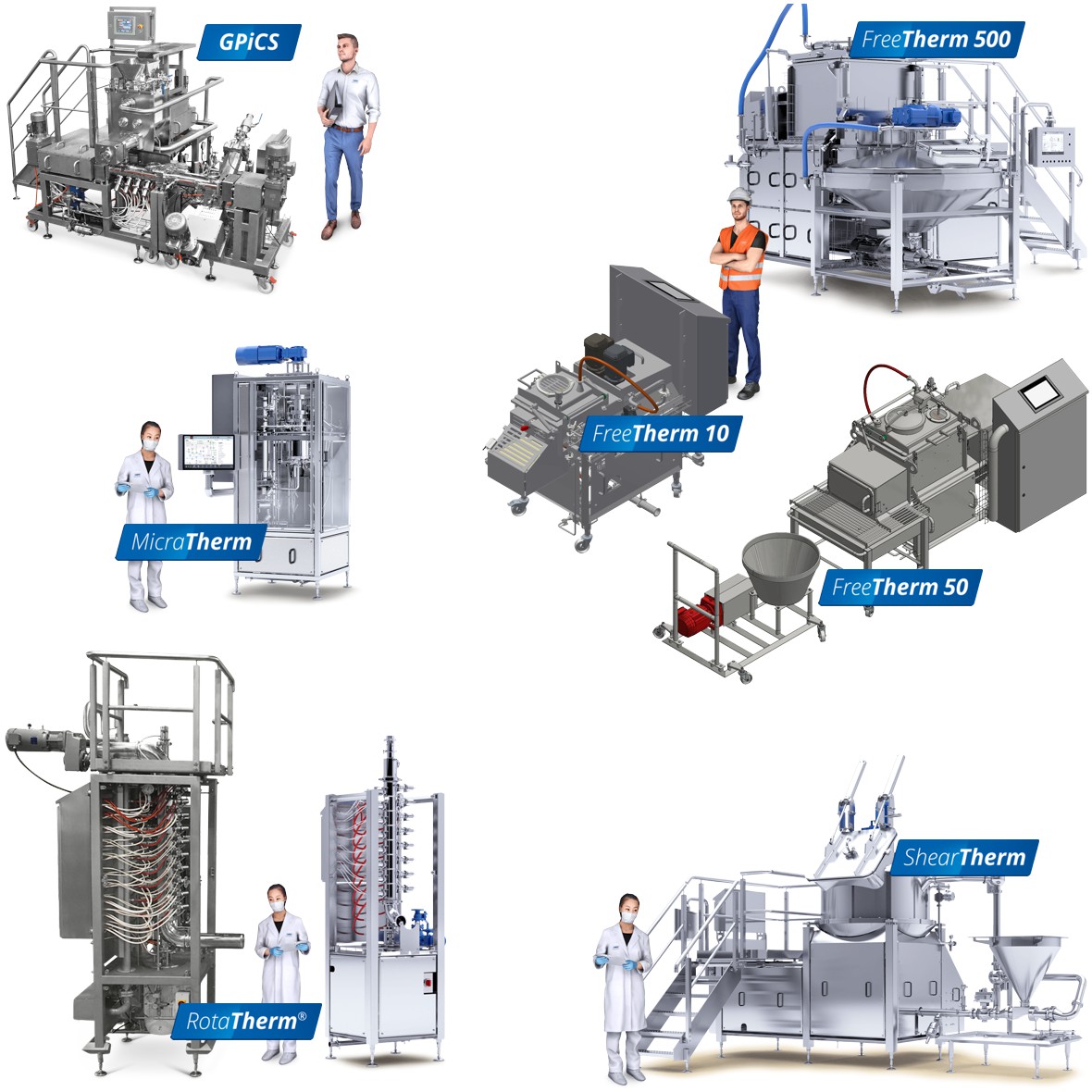

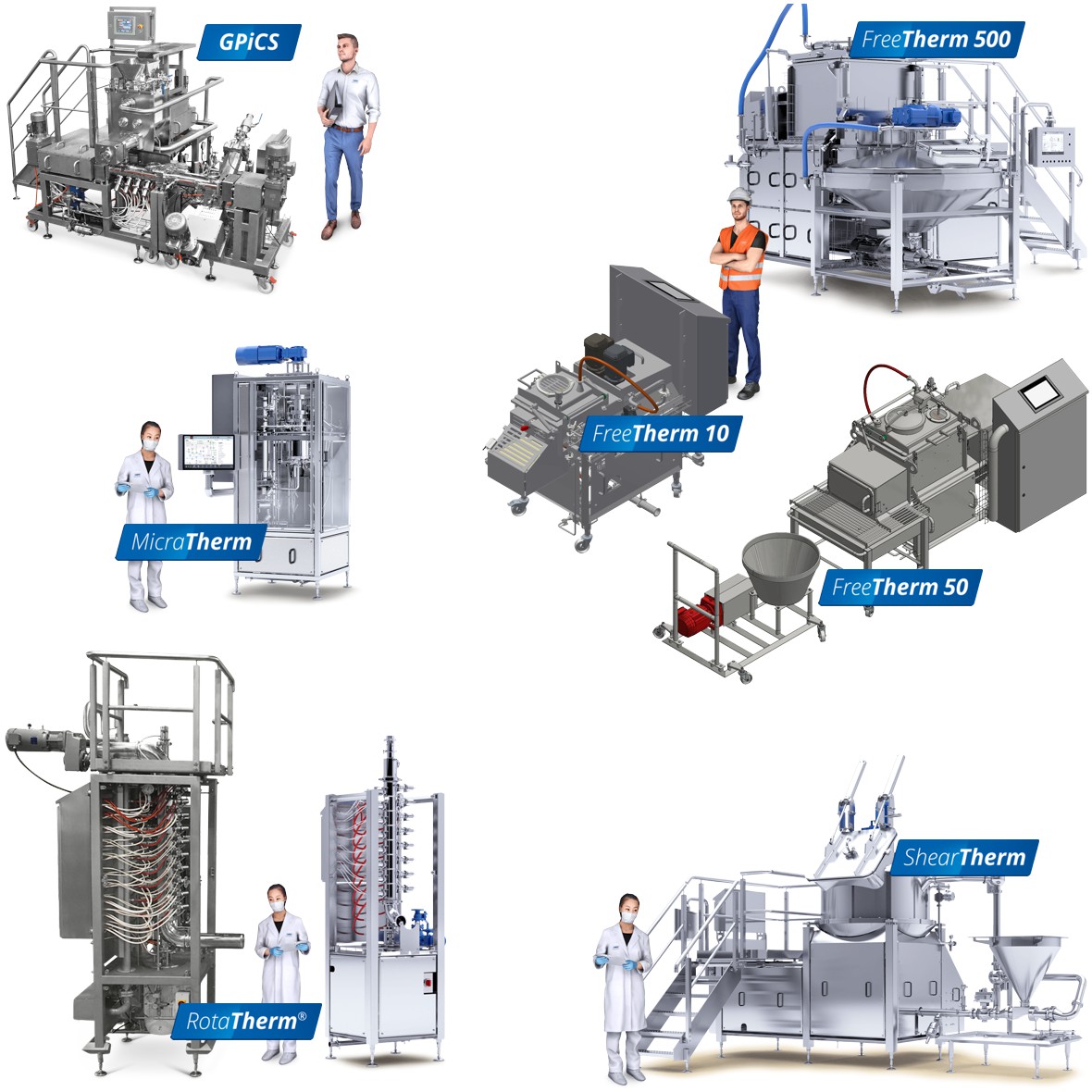

We custom build to your needs, but base it around our core machines (all pasteurise). It might be best to contact us to discuss the best options, but here is an introductory guide...

- RotaTherm® - The world's first and still leading continuous steam cooker, which can cook up to 17 tons (37,500lb) per hour (our smallest unit does up to 2 tons/h (4400lb)). It can cook at UHT and Aseptic levels.

- MicraTherm - An R&D scale steam batch cooker that replicates a RotaTherm's settings in 2-3kg (4-7lb) batches. It can cook at UHT levels.

- FreeTherm - A multifunctional steam batch cooker that blends and cooks up to 4x 500kg (4x 1100lb) batches per hour (our smallest unit does up to 4x 50kg (4x 110lb) batches/h).

- ShearTherm - An emulsifier and steam batch cooker that does fine particle foods at up to 2,400L (634gal) per hour (our smallest unit does up to 600L/h (159 gal)).

So, if you're doing big capacity or want Aseptic, RotaTherm® might be your core cooker, but if you want the smoothest blends, ShearTherm might be your choice. If you're doing lots of variety, it might be FreeTherm.

Why choose Natec steam injection?

- It's fastest and allows continuous cooking, so does higher volumes.

- It's healthy - it's not fried

- It best preserves nutrients and colours.

- It's hygienic - it cooks to pasteurise, UHT and Aseptic level, and nothing gets stuck to cooking surfaces.

- It's efficient - it uses less energy for each kg produced.

- It's low waste - Our systems create very little if any throw-away / give away.

- The RotaTherm® has a small footprint because it's upright.

- It has a low operating cost and a very high ROI.

- and more.

Contact us today to explore your best baby food processing equipment options.

Natec is famous for building systems based around direct steam injection cookers. Steam is the fastest way to cook, and it's healthy. Being fast, steam allows us to cook big volumes rapidly, and it doesn't burn out the nutrients and colours that other processes do. Our largest

Natec is famous for building systems based around direct steam injection cookers. Steam is the fastest way to cook, and it's healthy. Being fast, steam allows us to cook big volumes rapidly, and it doesn't burn out the nutrients and colours that other processes do. Our largest