Benefits

R&D

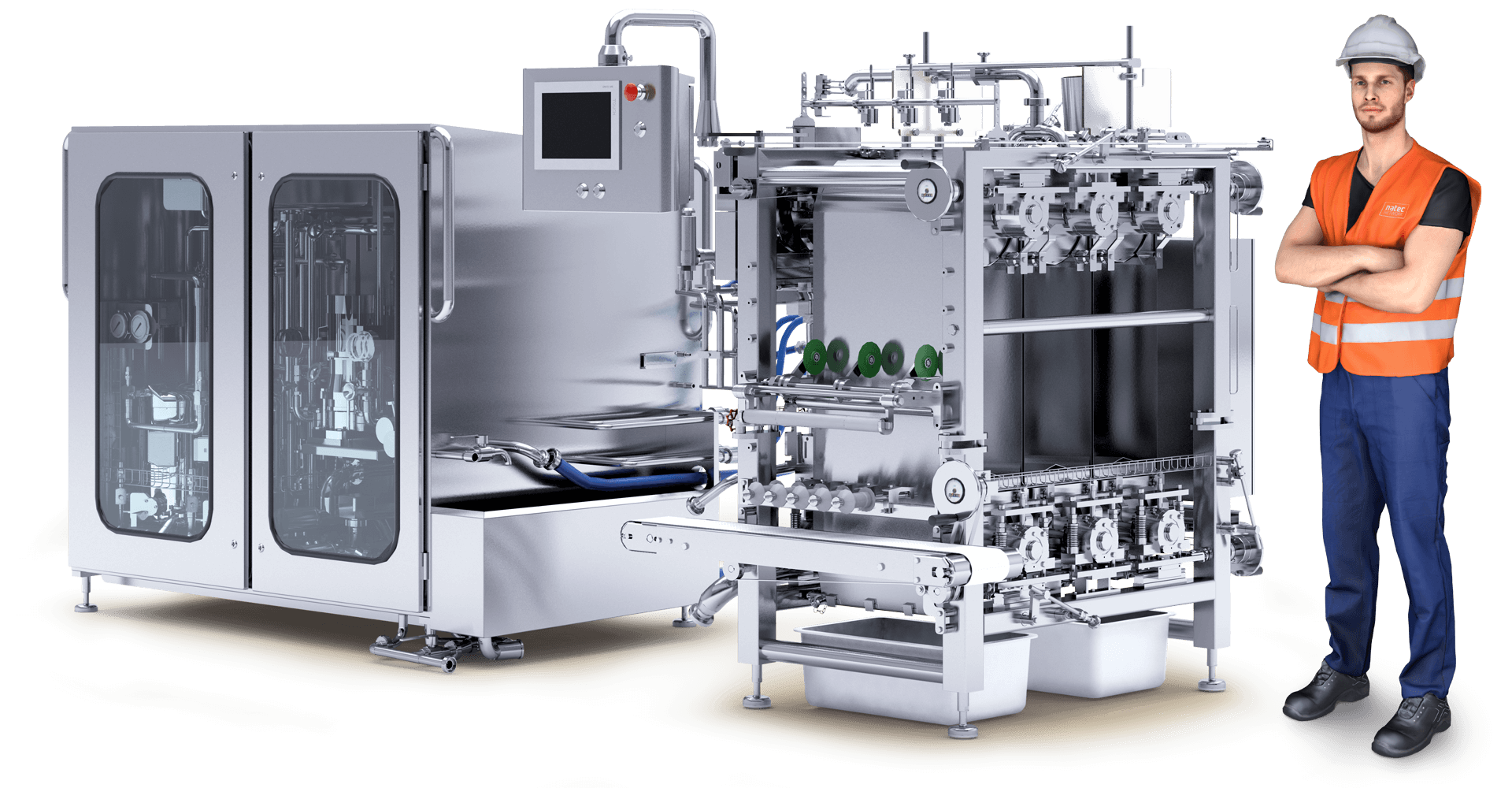

- For smaller productions or R&D facilities

Plug-in system

- 'Plug-in' system which does not need a lot of preparation as it is a stand alone unit

Highest flexibility

- Flexible in formats and cheese types

- Different add-ons make it highly flexible for any application