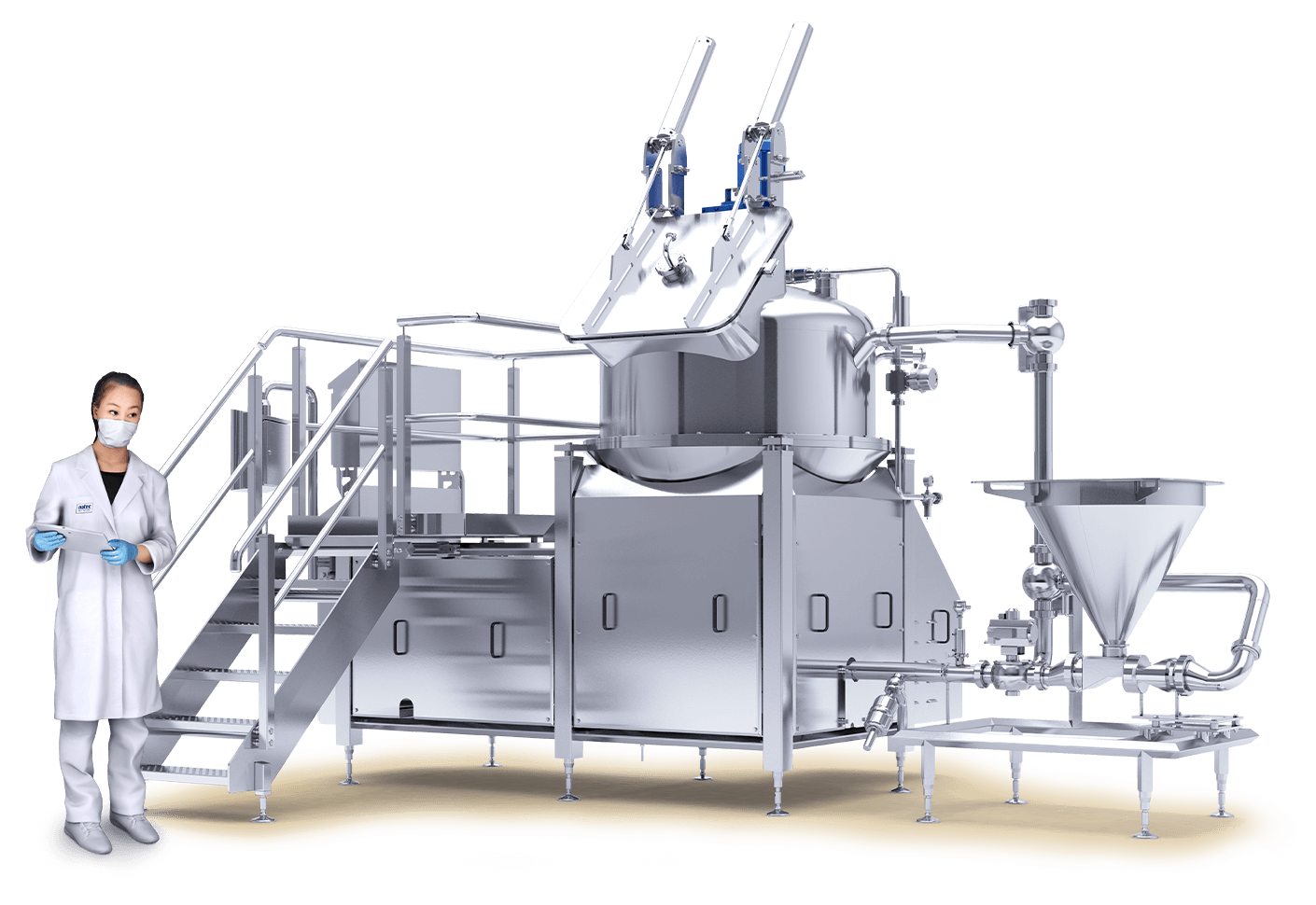

ShearTherm

Der Natec Network ShearTherm wurde speziell entwickelt, um grundlegende Prozessanforderungen und umfangreiche Scher- und Emulgieroptionen in einem modularen Design zu berücksichtigen, das individuell an die Kunden angepasst werden kann. Viele Prozesse werden auf der kleinen Stellfläche von ShearTherm kombiniert und gesteuert, was maximale Prozess-, Rezeptur- und Anwendungsflexibilität bietet. Bei vollständiger Kontrolle aller Prozessfunktionen liefert es hervorragende Eigenschaften und Qualität des Endprodukts – auch bei Partikeln!

Der ShearTherm ist die perfekte Wahl für hochkonzentrierte Pulverprodukte und pflanzliche Produkte. In Kombination mit unserer innovativen und einzigartigen Magnet for Emulsion (M4E)-Technologie sowie einem speziellen multidirektionalen Vormischer und Rührwerk sorgt es für ein kurzes und effizientes Mischen aller Zutaten .

Das integrierte Vakuumsystem und verschiedene Homogenisierungseinheiten, jeweils mit kontrollierter variabler Geschwindigkeit, garantieren eine sehr hohe Wiederholgenauigkeit, kurze Chargenzyklen und ein 100 % homogenes und klumpenfreies Produkt. Die Produkterwärmung erfolgt durch eine einzigartige direkte Dampfinjektion, während die Temperatur durch selbstreinigende Temperaturfühler genau überwacht wird.

Datenblatt herunterladen (Englisch)