Natec Network makes changing to continuous food processing equipment easy

At Natec Network, we are big supporters of continuous cooking systems. Compared to batch cookers that are still popular all over the world, continuous cooking offers benefits batch cooking cannot match, including:

- More efficient food manufacturing

- Less waiting time

- Longer production runs

- Fewer wash ups

- Faster heating

- Better quality, fresher tasting products

The value continuous cooking offers is undeniable. Thanks to these returns, Natec Network continuous cooking systems easily return their initial upfront investment.

Why choose continuous cooking food processing equipment?

Moving from batch to continuous cooking can be a challenging process. There can be a lot of resistance from within your business:

- The upfront costs seem too much

- Our current system does just fine

- Our current system will last a few more years

- We can’t afford the downtime it would take to set up

While each of these are valid concerns, the long-term benefits easily outweigh the downsides. Continuous cooking may hold the answer to your production issues. If you stick with your current process, you’ll never get to experience the following benefits unique to continuous cooking...

More efficient food manufacturing

Every production line demands downtime for cleaning, maintenance, consumable changeovers. So where does continuous soar? It drastically minimises this downtime required thanks to incredibly long runs - up to 156 hours between cleans, in fact! Natec Networks continuous cooking machinery is designed with clean-in-place (CIP) that allows you to clean your machinery with minimal effort and maximum peace of mind. CIP is automated without any (or minimal) human intervention so risk to your team is fully reduced.

Computer controlled systems automate the setup for production for each recipe. This minimises setup time and entry mistakes and makes optimising your production much faster and achieves more consistent results, increasing your overall efficiency.

Longer production runs and more output

Cooking doesn’t need to stop to cycle between batches - as long as ingredients are being fed into your system, cooking continues. Natec Networks food processing equipment can run for as long as 6.5 days without stopping for full cleaning. If your business focuses on high volume, then continuous cooking is perfect for you.

Faster heating and better products

Thanks to direct steam injection, our food production equipment is able to offer faster thorough cooking and a better tasting result. RotaTherm® uses multiple steam injection nozzles. Not only does this cook your food faster, but it also allows for better control, avoids overcooking, and ensures a more consistent (and therefore better-tasting) product.

Our equipment evenly heats and cooks your food product in just 15-20 seconds! Compare this to a batch cooker, which can take up to 40 minutes to reach a temperature that theoretically allows all the product to cook to the minimum, therefore resulting in a lot of overcooked product.

Moving from batch cooking to continuous cooking processes

Changing from batch to continuous cooking is a big investment. To make the change easier, we design custom systems specifically for you that works with your existing equipment and processes. During the consultation stage, our engineers work hard to ensure you’re getting not only exceptional equipment, but great value, too. While designing and optimising your cooking system, to understand your needs we ask you...

What type of product do you make?

Continuous food processing equipment has many advantages. It’s highly efficient and leads to better products… but it’s not for everyone. The first question Natec Networks engineers ask you is what type of product your business manufactures. For your product to benefit from continuous direct steam injection cooking it must:

- Be able to pass through a pipe

- Be able to accept moisture during the cooking phase (from the direct steam injectors)

- Be blended up all at once upfront

This determines whether our continuous food processing equipment is suited for your needs. Based on this, we design a custom plan - some clients may be recommended an entire new line, while others may need various pieces of core or ancillary equipment to slot into their existing line and fix bottlenecks.

How much food do you manufacture?

The biggest strength of continuous cooking is its ability to produce food non-stop. If your business produces over 1000 kg/h, continuous cooking systems are ideal for you. Longer production runs - up to 156 hours straight - mean you can increase your output further.

Of course, if you only manufacture small runs may not be your key concern. However, even smaller production lines can benefit from continuous cooking if you’re dedicated to and place value on producing high-quality product - even at smaller volumes.

We review your current production system.

Not all businesses need to replace their entire production system to start enjoying the benefits of continuous cooking.

If your production is plagued by bottlenecks, we can help.

Many of our ancillary equipment modules can be installed and integrated independently without needing major work on the entire production line.

During a review, we identify points where your process could be improved which in turn improves your production!

We then recommend standalone pieces of machinery or processes that could immediately help eliminate congestions and improve your production process.

World-class food processing equipment from Natec Network

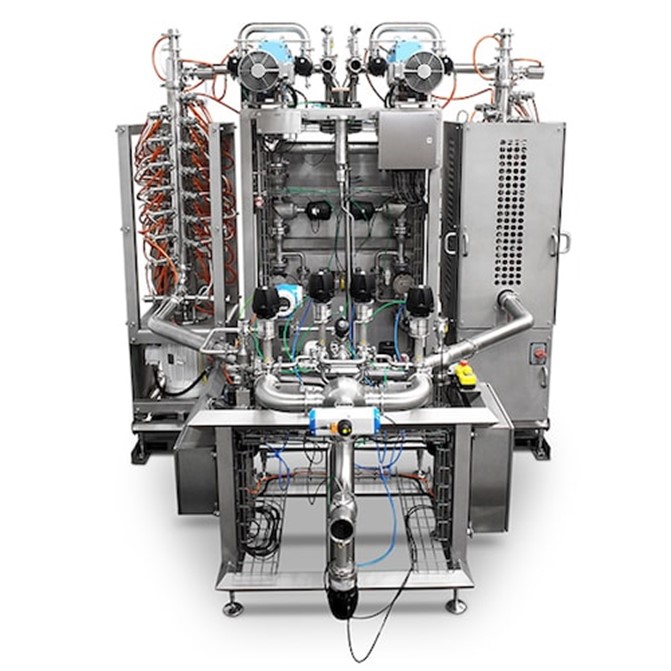

Moving from batch cooking to continuous cooking requires investment in appropriate food production equipment but not just in any continuous food processing equipment but in efficient world leading continuous food production equipment like the RotaTherm® from Natec Network. While the upfront investment may scare some, the results speak for themselves:

- 156 hours (6.5 days) of non-stop production

- Even, consistent heating in just 15-20 seconds

- Systems for Anywhere between 50 kg/h and 17,000 kg/h production rates

- 30% increase in productivity and 10% reduction in ingredients required!

Those are just some of the core performance numbers that our food production equipment have achieve for their customers year in and year out. Our machinery is trusted by major companies all over the world. We have a global network of locally-based engineers, technicians and representatives as well as remote support. This allows us to offer five-star service and solve your production problems - no matter where you are.

How can we support you?

Talk to us about the industrial cooking needs of your project!