M4E technology

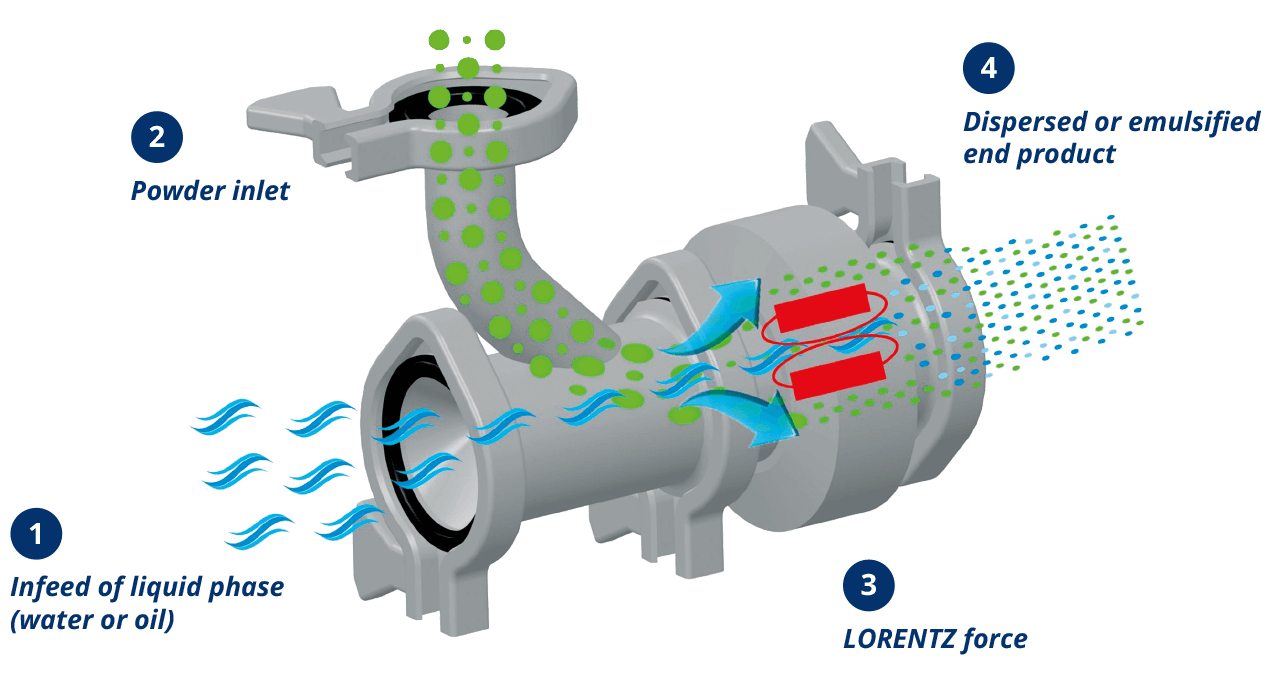

The Magnet for Emulsion technology (M4E) combines turbulent flow conditions with the LORENTZ force induced by a permanent magnetic field. In a turbulent flow, particles (powder particles or oil droplets) spin around and collide. This results in particle deformation and break-up.

The innovative way to make emulsions and dispersions.

The LORENTZ force will further intensify this spinning and colliding effect. As such, the combination between the turbulent flow conditions and the LORENTZ force create the perfect environment to make stable emulsions and lump-free powder dispersions. The M4E technology is mainly an “one-pass” technology, meaning once the product has passed the magnet, it is perfectly dispersed and / or emulsified.

The innovation

By pumping a liquid through our device, a vacuum is created by the venturi effect. Thanks to this vacuum, the powder is aspired and introduced into the liquid phase. Once in contact with the water or oil, powders have the tendency to coagulate and create lumps. Thanks to our innovative technology, immediately after the powder introduction, the mixture passes through our patented device creating perfect, lump-free dispersions.

Benefits

- Reduced energy costs with increased savings

- Higher yield and reduced raw material consumption due to reduction in thickener requirements (starches, hydrocolloids)

- Easy cleaning and low maintenance

- Highest user friendliness and application flexibility – including products with particles (without changes to hardware or software)

- Continuous process and reduced production time

- Lower investment cost and smaller footprint