Big capacity wet pet food production: 20 tons per hour!

The Natec Network builds full wet pet food production lines. At the centre of it, though, is our world-leading RotaTherm®.

The Natec Network builds full wet pet food production lines. At the centre of it, though, is our world-leading RotaTherm®.

RotaTherm® is the world's original and still easily the best continuous steam cooker. For pet food, it can cook up to an extraordinary 20 tons (20,000kg, 44,000lb) per hour for up to 156 hours continuously between fast CIP cleans. (We also have smaller RotaTherm®s if you're not at 20 ton level, or FreeTherm if you're looking for a steam batch cooking alternative).

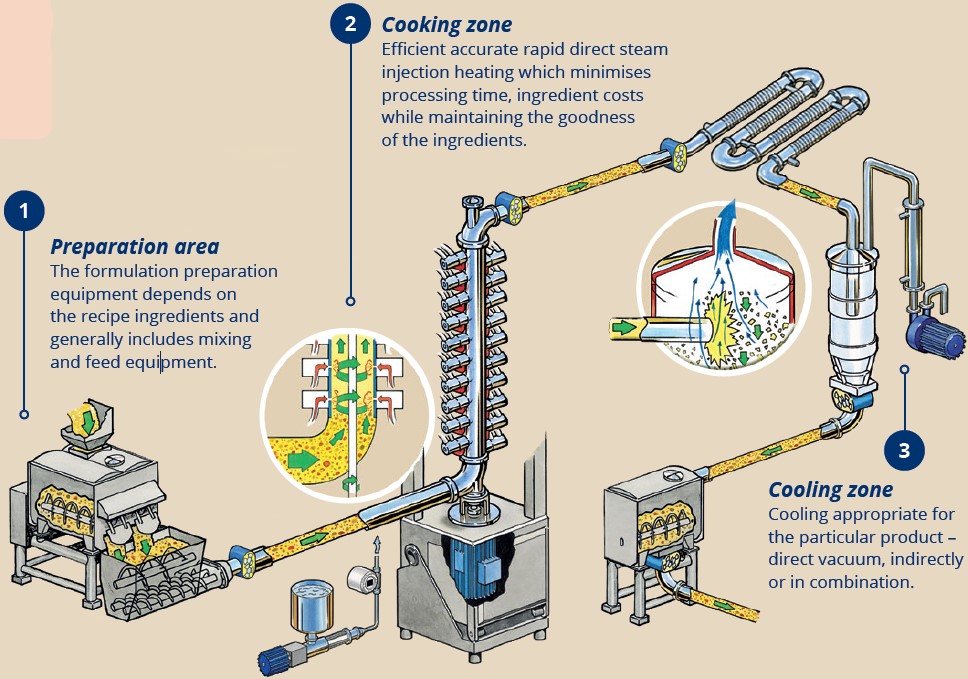

How is our pet food forming equipment so productive? The ingredients are pumped through a tube where the are mixed and pass through a series of steam injectors. The injectors rapidly pump steam into the ingredients, cooking and moistening them. Steam is the fastest way to cook. The heat penetrates the food, but it does it quickly. As such it has minimal impact on colour and nutrients, leaving the food looking and tasting better than alternative methods.

Pet food forming equipment for long shelf-life

Our RotaTherm® process cooks at pasteurisation, UHT and Aseptic levels. This destroys the bacteria, allowing for much longer life. Unlike other machines, our precision tubes and injectors don't catch and hold any food. It's stuck food particles that cause other machines problems and a lot of waste. RotaTherm® is famous for big production, minimal waste, low operating costs and a fast ROI.

Best quality

for your pets

People love treating their pets. They want quality food for reasonable prices. Manufacturing pet food means most likely a combination of cereals, vegetables particles and meat. Natec Network systems will give you excellent results with a long stable shelf life.

Enquire today about our world-leading pet food forming equipment.

The Natec Network builds full wet pet food production lines. At the centre of it, though, is our world-leading

The Natec Network builds full wet pet food production lines. At the centre of it, though, is our world-leading