Benefits

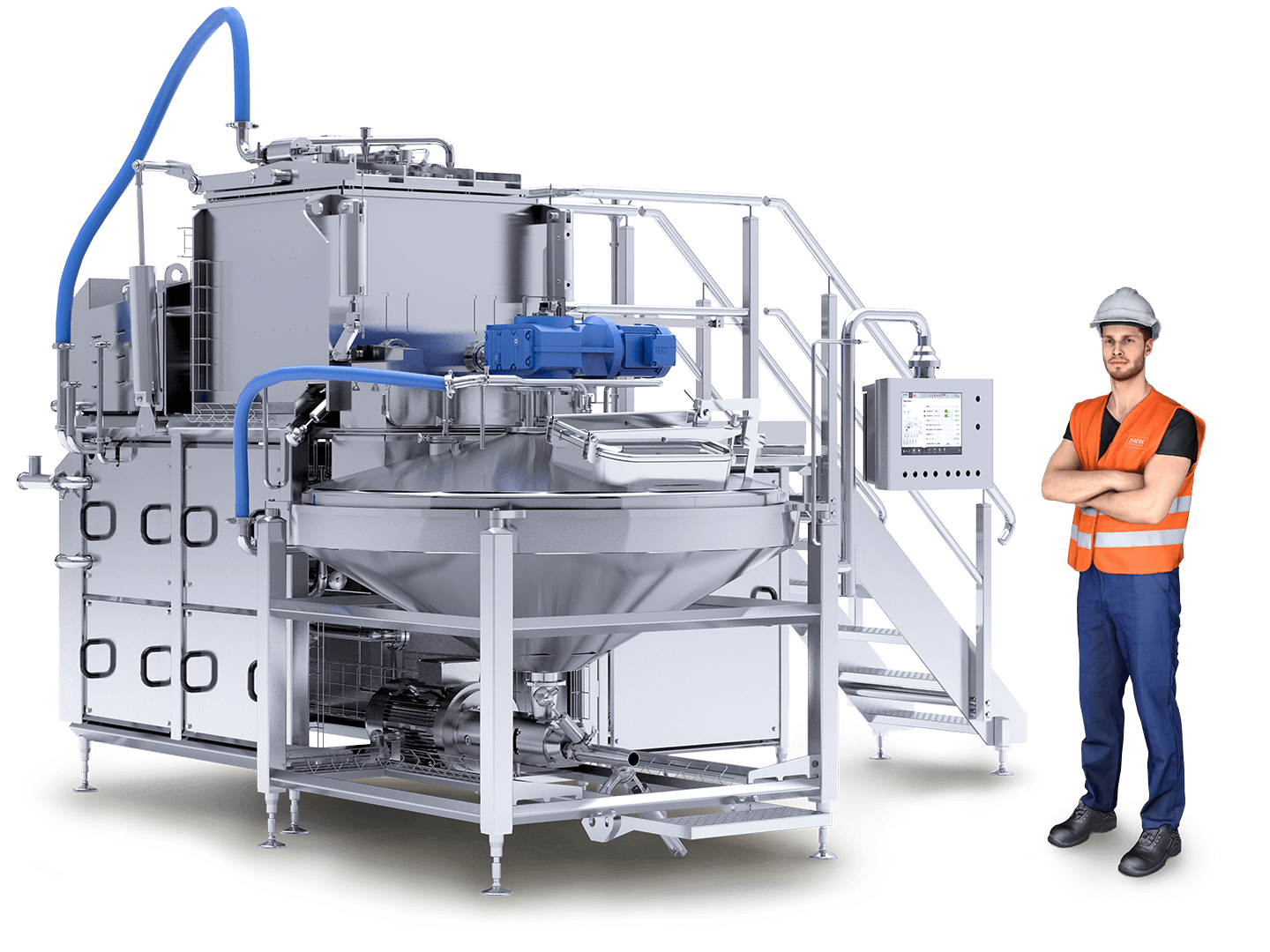

Multifunctional

- Multifunctional batch processing system for cost effective production, providing excellent finished product quality

Highest flexibility

- Mixing pattern flexibility increases blending and heating efficiency

Direct steam injectors

- Effective heating using unique direct steam injectors which eliminate product hotspots

Vacuum system

- Integrated vacuum system for de-aeration for density control and colour stability

Clean-In-Place

- Different automatic programs for easy production and CIP

- Fully enclosed, CIP able, hygienic design ensuring product safety

Central control surveillance system

- Central control and surveillance system for high operator comfort