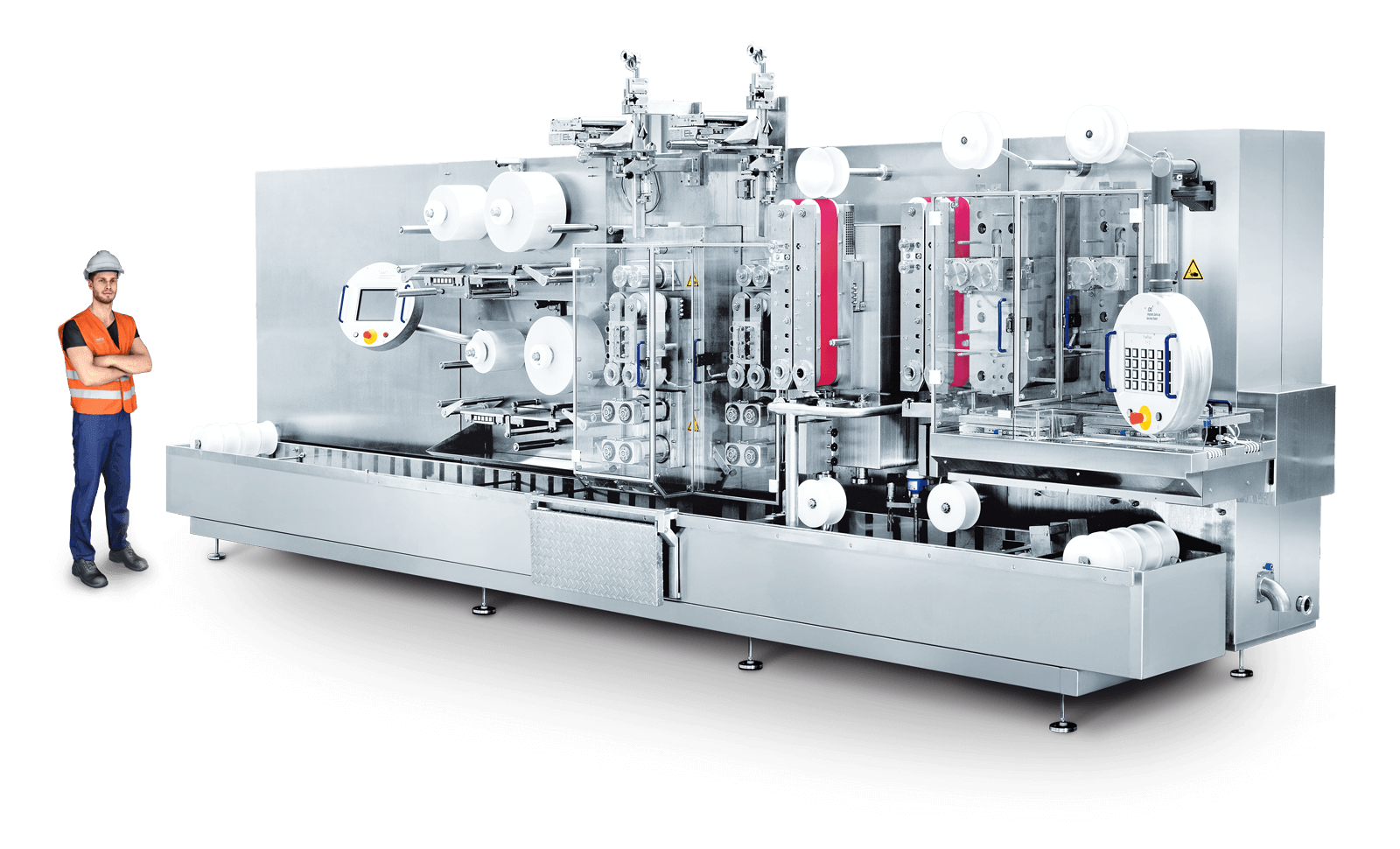

Benefits

Plastic foil reduction

- Plastic foil need reduced by 20 % due to small and efficient welding seams

Exact piles

- Unique cutting and stacking technique which arranges and coordinates individually-wrapped slices into exact piles

Central control surveillance system

- High operator comfort and trouble-free production thanks to the central control surveillance system

Less give away

- Minimal give away thanks to our unique implemented weight control system

Twin production

- Twin production: each of the two independently operating lanes produces up to 1,100 slices per minute - this makes the production of two different cheese types at the same time possible