Benefits

Cost reduction

- Reduction of rework costs

Reusage

- Reusage of the products

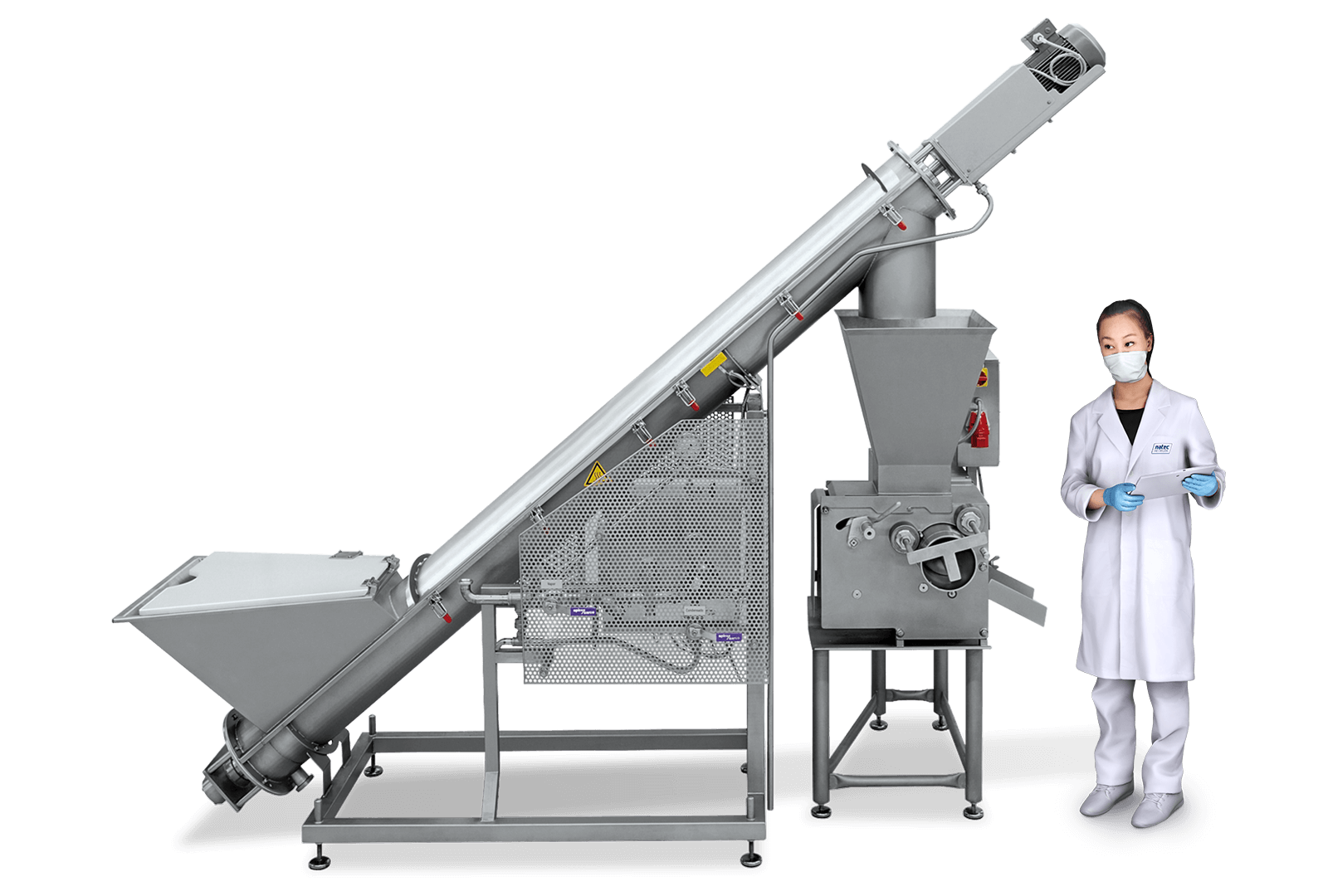

Separating packed products from wrapped material.

The Natec Network Separating Machine is designed to separate packed products from the packaging material. The separated products can be used as rework. This machine can be loaded with single packed IWS slices (with or without secondary packaging), processed cheese wedges or processed cheese in plastic cups.

It is sometimes used in conjunction with our FreeFilter. FreeFilter continously cleans filters, allowing up to 120 hours between filter changes.

Cost reduction ReusageBenefits

For additional functionsOptions

or different execution

processed cheese wedges wrapped in aluminium and cups up to 400 g (14 oz) loading by conveyor belt

Machine data Utilities Cleaning ExecutionTechnical data