When experience connects with engagement

Successful engineering in the food processing industry is based on multi-layered experience coupled with intensive commitment to the continuous development of even better solutions.

Since 1974 Natec has been an expert in the production of processed cheese. The direct access to the Hochland production site offers the unique advantage of continuous improvement of the machines in maintenance, hygiene, operational and production safety.

The Natec Network particularly supports customers with key sustainability requirements in food production, such as reducing the amount of plastic film used to create less waste or extending the best before date to meet the demands for longer lasting food.

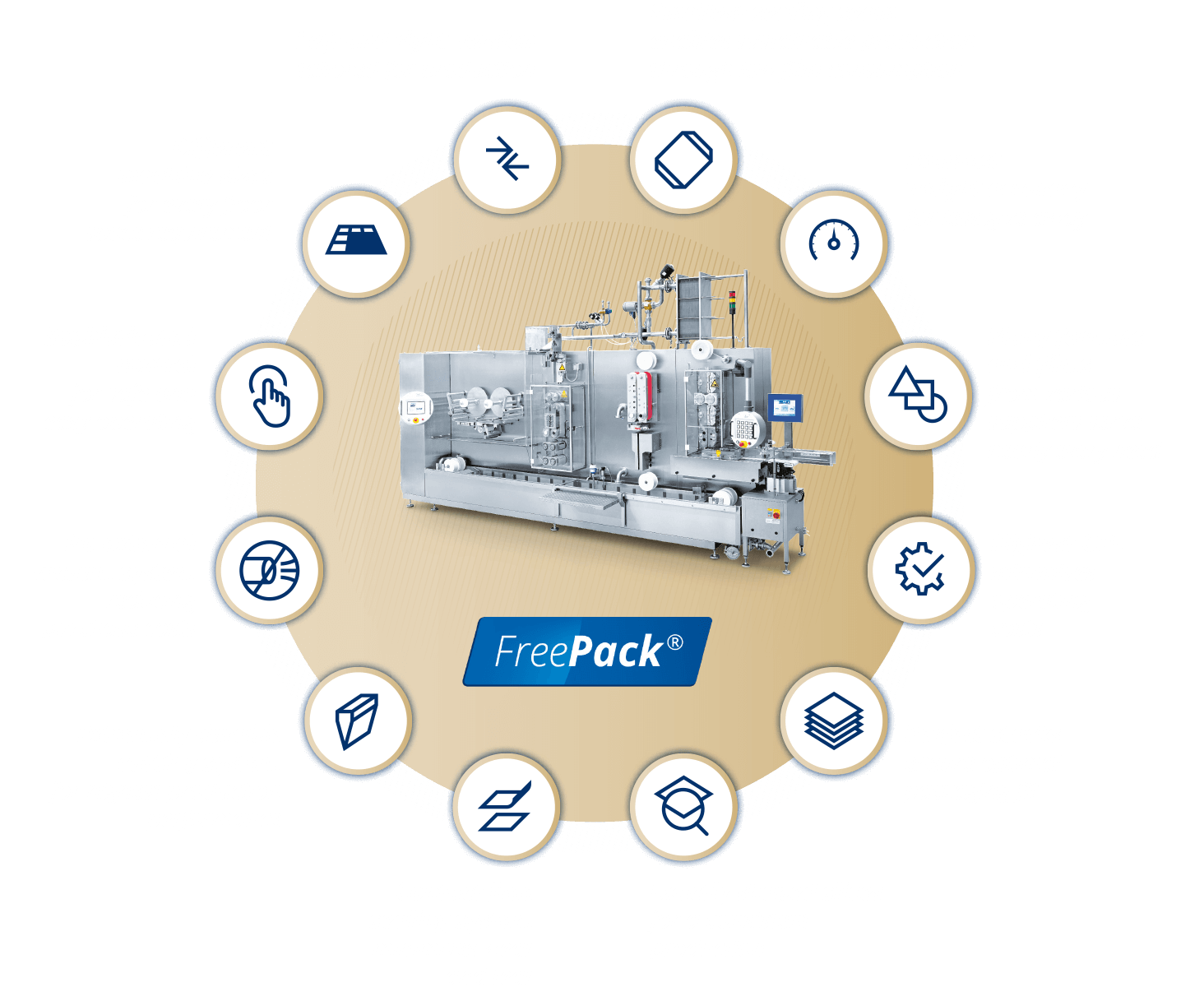

The result: reduced production costs through resource savings while increasing flexibility and profitability. That´s why the FreePack® has been the best-selling equipment for IWS production.

With the Natec Network FreePack®

we focus always on your specific needs:

Marketing

management

With the Natec Network FreePack®, you achieve high sales through maximum customer satisfaction.

Project

management

With our high-performance equipment, you not only realise your goals, but also receive a positive impact on your ROI.

Research &

development

Our flexible and customised solutions meet all your requirements in terms of the best working formulation.

Maintenance

& operations

Our high-quality equipment not only has maximum technical safety, but also secures you the fastest possible restart of production.

Perfect synergy for IWS production

Natec Network´s Unique Technical Performance (UTP)

The combined features of the Natec Network FreePack® offer optimal synergy and thus unbeatable advantages for your IWS production. Unique patents protect the maximum efficiency, productivity, reliability and sustainability this equipment provides within the food processing industry. You benefit from minimised operating costs, minimal space requirements and hardly any wear. The consumer receives a safe, easy-to-use and high-quality food product.

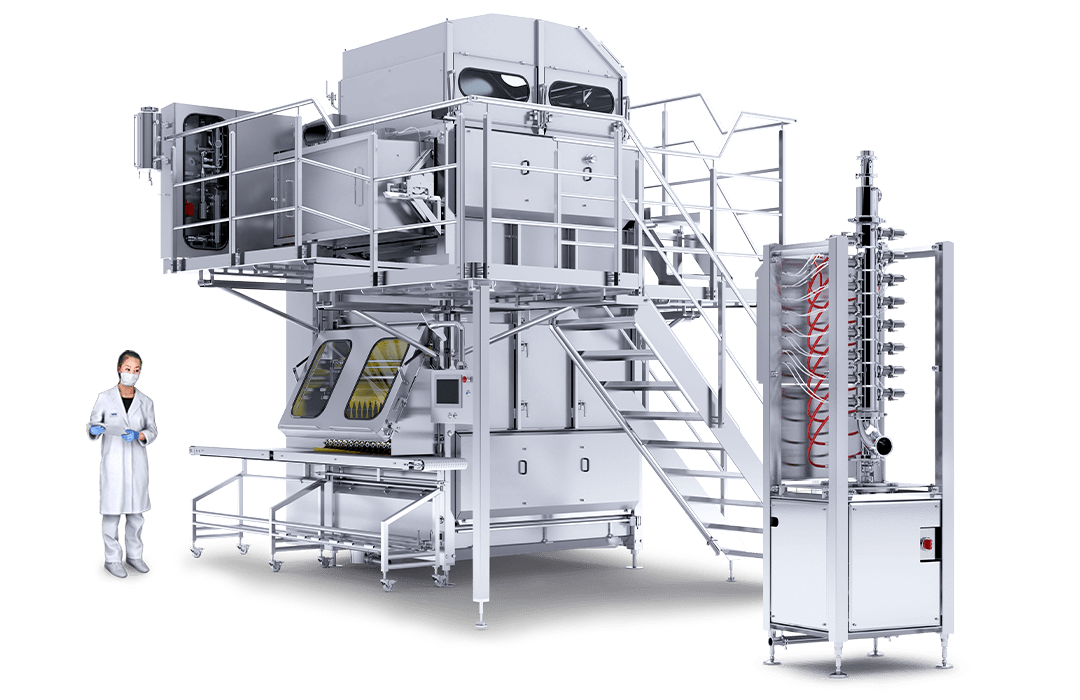

Conditions changed? Exchange your equipment!

As your company develops, its goals change – and with them the demands on your production environment. It is usually not enough to make adjustments at one process step, but to look at the performance of the entire line and update it in a powerful way.

When upgrading your IWS production, we support you with leading expertise for complete processed cheese solutions. Always aiming for fully automated lines designed for the needs and turn-key manufacturing solutions for every step of your evolution.

Talk to us about your situation and benefit at any time from our FreePack® rebuy program.

Technology for the finest

You also produce other processed cheese products, cream cheese, pasta filata, soups and sauces, meat or plant based products, baby food and more? We support you with innovative, powerful technology and the right equipment.