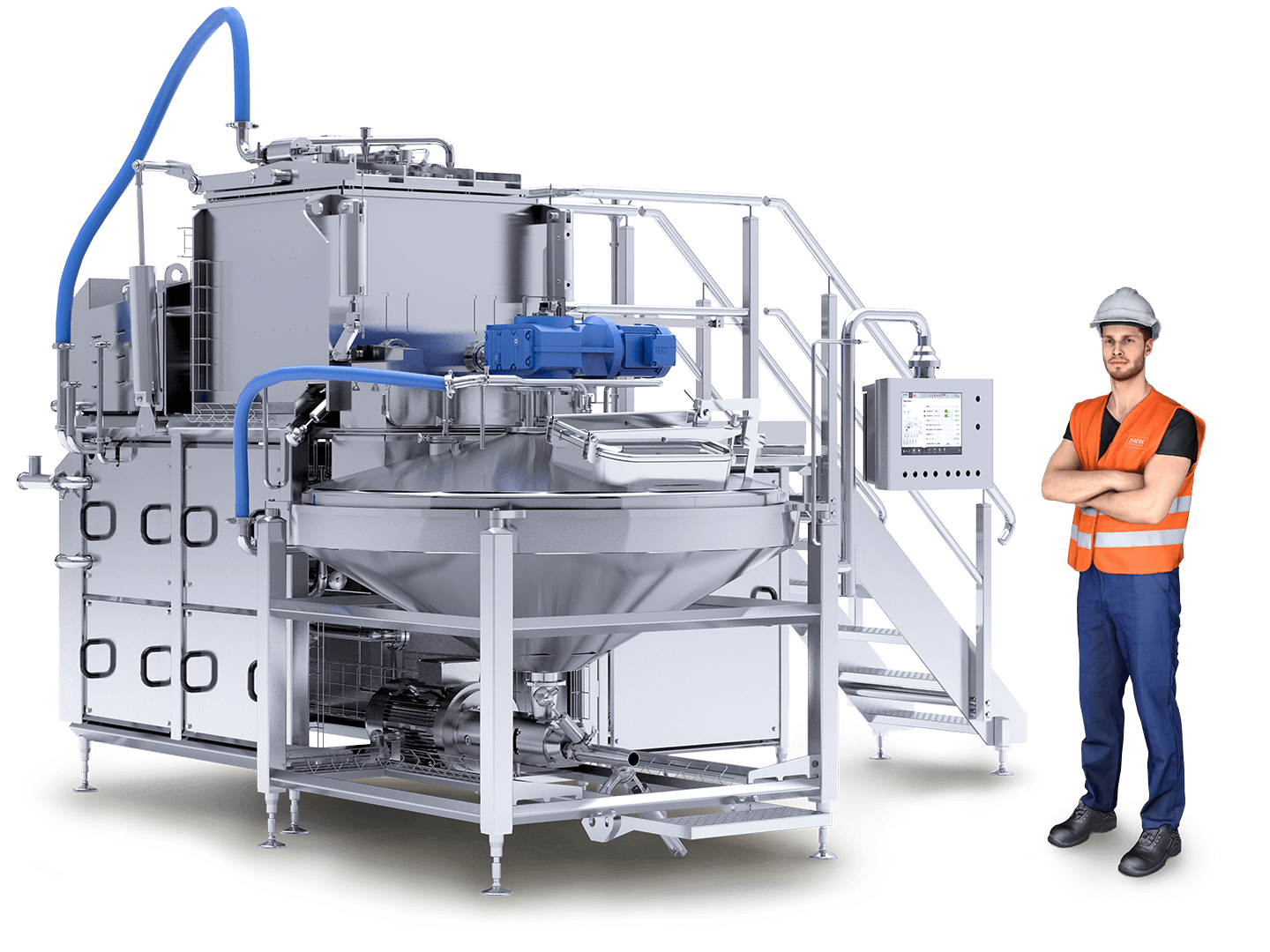

FreeTherm: Batch cooking from direct steam injection specialists

The FreeTherm is Natec Network’s batch processing system that mixes, blends, cooks and de-aerates, a wide range of (food) products.

Example of food products made with the FreeTherm

We manufacture the FreeTherm in Australia and specialize in industrial Direct Steam Injection (DSI) cooking systems, led by the RotaTherm® continuous cooker.

FreeTherm batch cooker from the leaders in DSI cooking

The FreeTherm brings elements of the proven efficient and effective RotaTherm® continuous cooking & processing technology to batch food production:

- Processing a complete range of product type, viscosity and composition - including value added products which have a (food) oil base)

- Featuring unique steam injector and temperature measurement technology.

- Delivering high production efficiency through sophisticated mixing and heating design.

- The FreeTherm’s highest flexibility in blending and heating means the maximum quality and performance for your production line.

FreeTherm batch cooking range widely suitable

The FreeTherm is suitable for new businesses through to global players,

- Available with batch sizes of 50, 150, 250 & 500 kg

- Achieving production rates of 100 – 2,500 kg/h

- Stand alone or for integration into existing production lines

FreeTherm 150 - 3D with bin lifter, built & mixing / blending augers

Origins of FreeTherm batch cooker

The FreeTherm shows the result of the purposeful innovativeness through a total customer focus of the Natec Network expertise. Its name represents this unity of Germany and Australia:

- ‘Free’ comes from FreeSlice® and FreePack® which are Natec Network´s (Germany) renowned forming and filling equipment for SOS & IWS processed cheese

- ‘Free’ also communicates the freedom of the capabilities and functionality of this food technology

- ‘Therm’ is from Melbournes continuous cooking RotaTherm® and R&D MicraTherm

- ‘Therm’ also refers to the changes in the thermal energy of the food product through the process

There are many more functional features and benefits than listed here so please visit FreeTherm dedicated pages online. Or contact us with your questions and project requirements.

A new friend for the FreeTherm is coming

A further extension to the cooking range of the Natec Network is on its way: The ShearTherm!

This batch cooker is purpose designed for high shear mixing of high powder content recipes to achieve homogeneous fully hydrated, blending and cooked product.

Global support from the Natec Network

The Natec Network offers a wealth of knowledge and support with every project and installation drawing on its many years of experience in high-quality machinery and plant engineering for the industrial food production sector.

They are specialists in the development and engineering of machinery and plants for the production, processing and packaging of all types of processed cheese and other types of processed food, in batch systems or sophisticated continuous systems from us.

The distinct innovative culture within the Natec Network group characterizes them. The aim of their work is your optimum value creation.

A sense of responsibility, product quality, pleasure and nutritional value are at the forefront of food production. The Natec Network embrace this and are experienced in all related requirements, from hygiene right up to appetizing appearance of the final food.