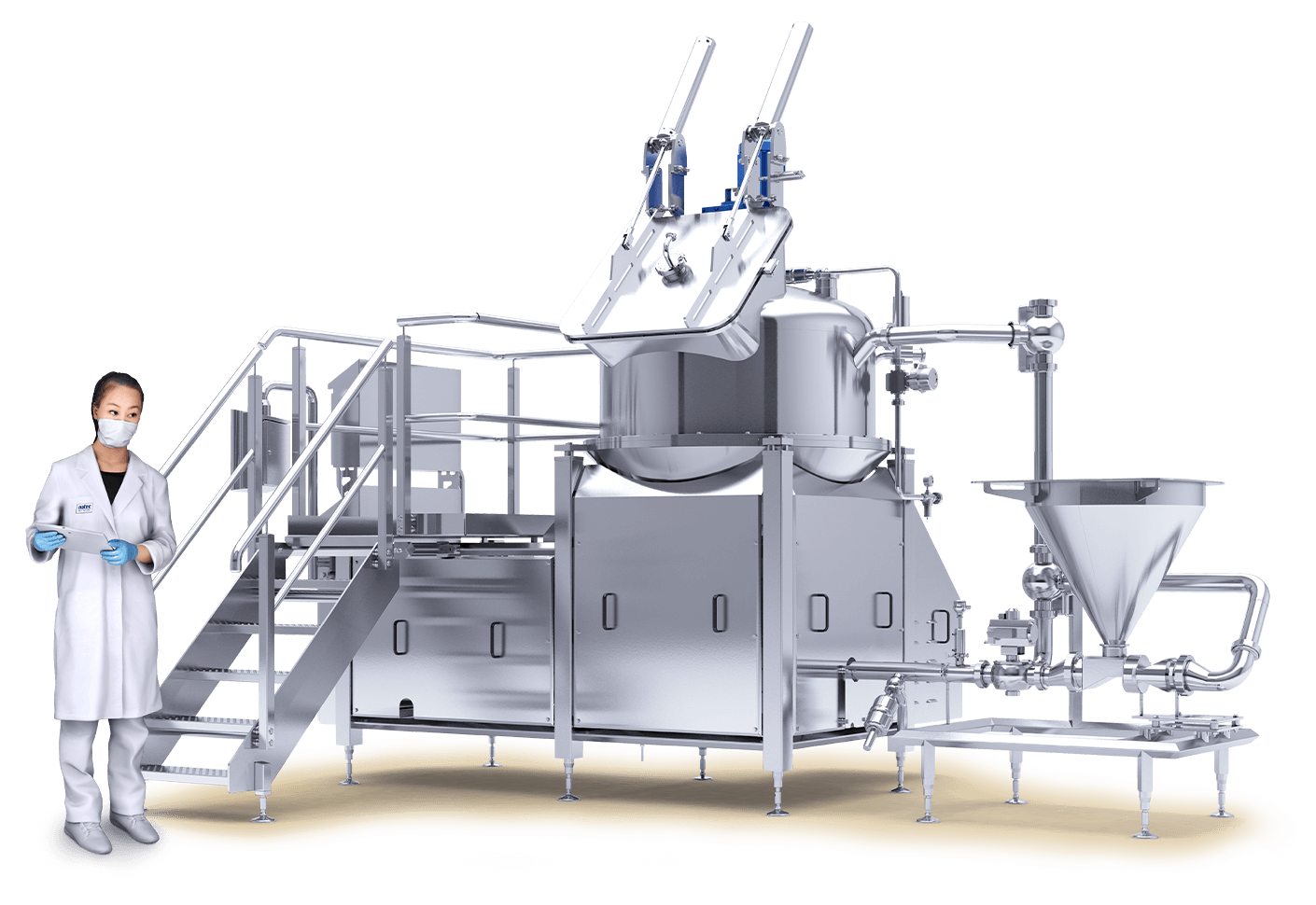

ShearTherm

The Natec Network ShearTherm is specifically developed to include basic process requirements and extensive shear and emulsification options, in a modular design that can be individually adapted to the customers’ needs. Many processes are combined and controlled in the small ShearTherm footprint, delivering maximum process, recipe and application flexibility. With full control of all process functions it delivers excellent finished product characteristics and quality – even with particles!

The ShearTherm is the perfect choice for high powder concentrated and plant-based products. In combination with our innovative and unique Magnet for Emulsion (M4E) technology, together with a special multi directional pre-mixer and agitator, it delivers short and efficient mixing of all ingredients.

The integrated vacuum system and different homogenisation units, each with controlled variable speed, guarantees a very high repeatability, short batch cycles,100 % homogeneous and lump free product. Product heating utilises unique direct steam injection while temperature is accurately monitored by self-cleaning temperature probes. It can pasteurise.

Download datasheet