Passion for diversity in food processing systems

Natec Network's food processing machinery enables a wide range of food to be produced at an exceptionally high standard. We offer more than 30 professional solutions for your specific requirements, from the initial idea right through to the finished product. With our customised systems, you are guaranteed safe and efficient production processes for pasteurisation, UHT, high shear, batch and continuous cooking.

Cutting-edge equipment for a comprehensive range of products

We provide complete functioning lines for food products such as processed cheese, pasta filata / mozzarella, soups, sauces, dressings, mayonnaise, meat products and fruit and vegetable purees. Specialty foods such as bakery cream, mayonnaise, baby and infirmed food, pet food and many more can also be processed with the highest quality and control.

Our unique Benchineering® approach

The combination of more than 30 different process solutions in various applications is only possible through a holistic, customer-oriented approach. Benchineering®, a model created by the Natec Network, promises support from concept creation to the finished product and beyond. No matter what stage of business you are at, the Natec Network's team of experts are dedicated to working with you throughout your business evolution.

Which Natec Network system works for you?

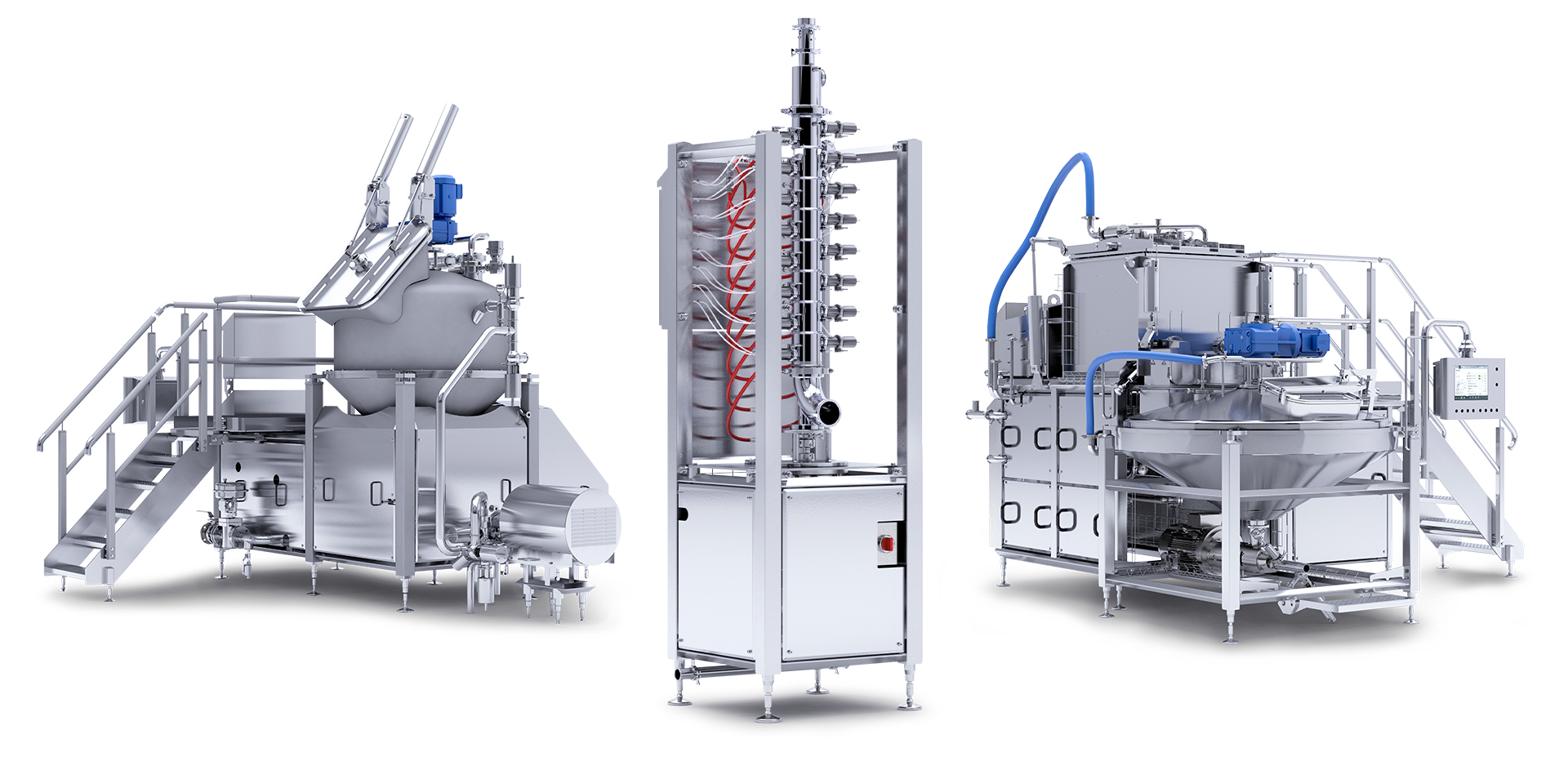

For capacities from 100 kg with multiple recipes, versatile batch cooking systems such as the FreeTherm or ShearTherm would be the best solution.

Our innovative cooking range examples - ShearTherm, RotaTherm & FreeTherm

Also using superior Direct Steam Injection technology, the RotaTherm® produces clean dairy products such as processed cheese, mayonnaise and sauces completely free of burnt specks and particles. Conversely, taco meat, which is characterised by its distinctive texture, maintains its chunky form.

With Natec Network equipment, smooth purees and easy-to-chew foods have a short processing time, delivering flavour, freshness, natural colour and a stable shelf life. Perfect for purees, baby food, soups, chunky dips, smooth flavour sauces and more! Our food processing machines also improve the viscosity, texture, and quality of processed block and slice-on-slice (SOS) cheese.

Do you manufacture pet food? Natec Network's high-quality pet food processing equipment helps companies abide by strict safety parameters, while controlled processing maintains consistency, quality, and texture.

Ideal for natural mozzarella, string cheese, and pasta filata varieties made from fresh curd, we have Natec Network’s GPiCS Mozzarella Cooker Stretcher. This system removes the need for bath water, saving many litres of water from being used while producing a stellar product consistently!

Natec Network’s ancillary equipment complete a line providing you accurate control over the entire process and all from one supplier. (Psst! There are models available with lower production rates, so don't hold back asking us about your requirement!)

Experience you can trust

"Our core food processing equipment is individually configured, delivering superior results to global companies daily," says Harry Miess, Managing Director at Natec Network. "We embrace the drive of combining proven technology with innovation that leads to customer-specific adaptions".

Your company will be at the forefront of the food processing industry with Natec Network's cutting-edge equipment, with the group's cooking equipment designed and manufactured in Melbourne, Australia.

Natec Network has operated on a global scale from the beginning, so shipping to and supporting our international customers is a large part of our business.