Benefits

Production details

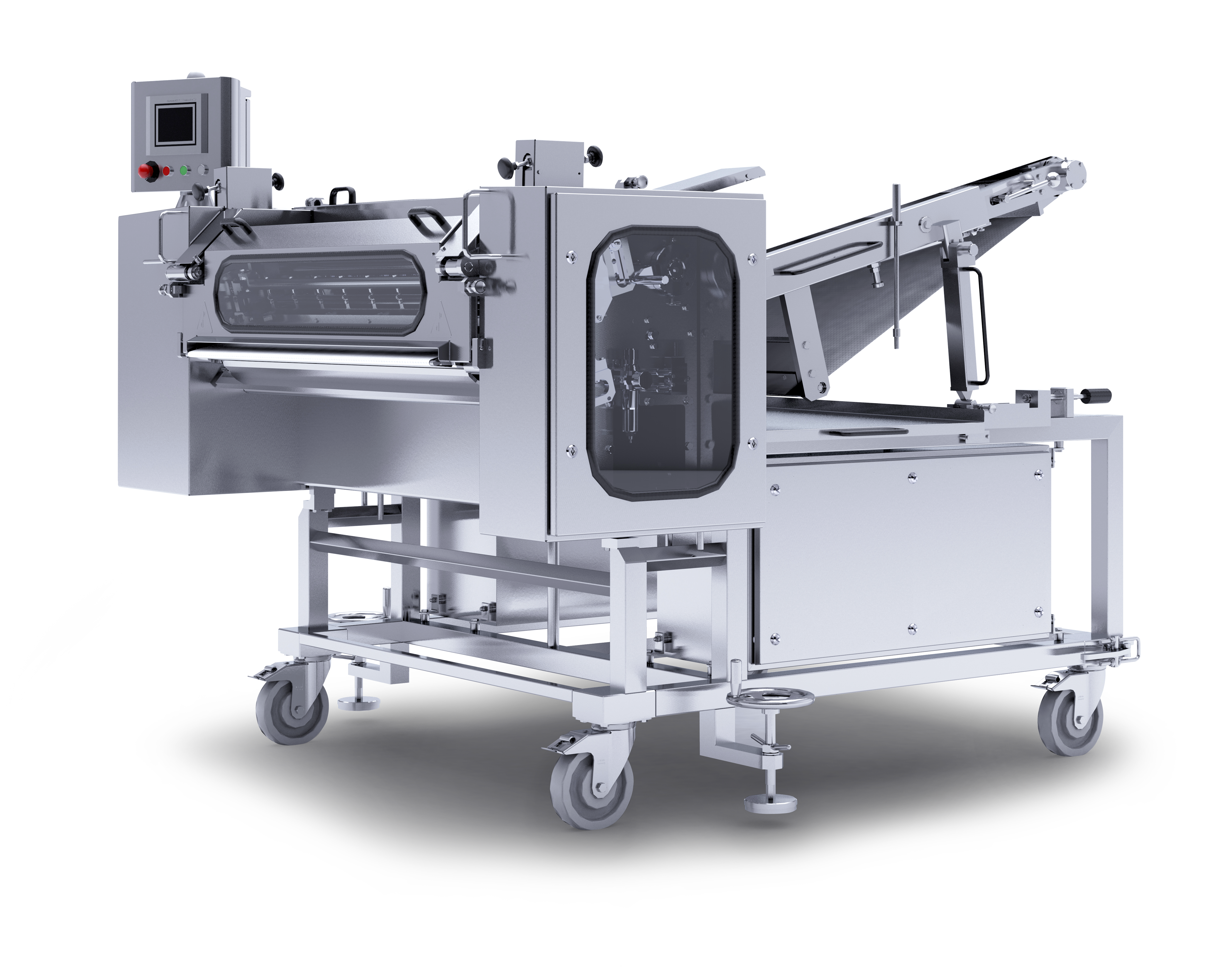

- Inline production of processed cheese sticks (forming, cooling and cutting in one step)

- Production of sticks of exact dimensions

HMI

- Different formats can be set on HMI

Length changes are possible

- Possible changing of the length from 50 mm up to 135 mm without mechanical modification

Cheese types

- Can be used for processed cheese, analogue or hybrid cheese

Movable

- Movable on rollers