Meat rendering equipment, defatting machines

Natec builds and sells world-leading industrial meat rendering equipment, or defatting machines, to your needs. That 95% fat-free mince / ground beef in the supermarket often comes from our machines. Contact us or read on...

Meat rendering equipment

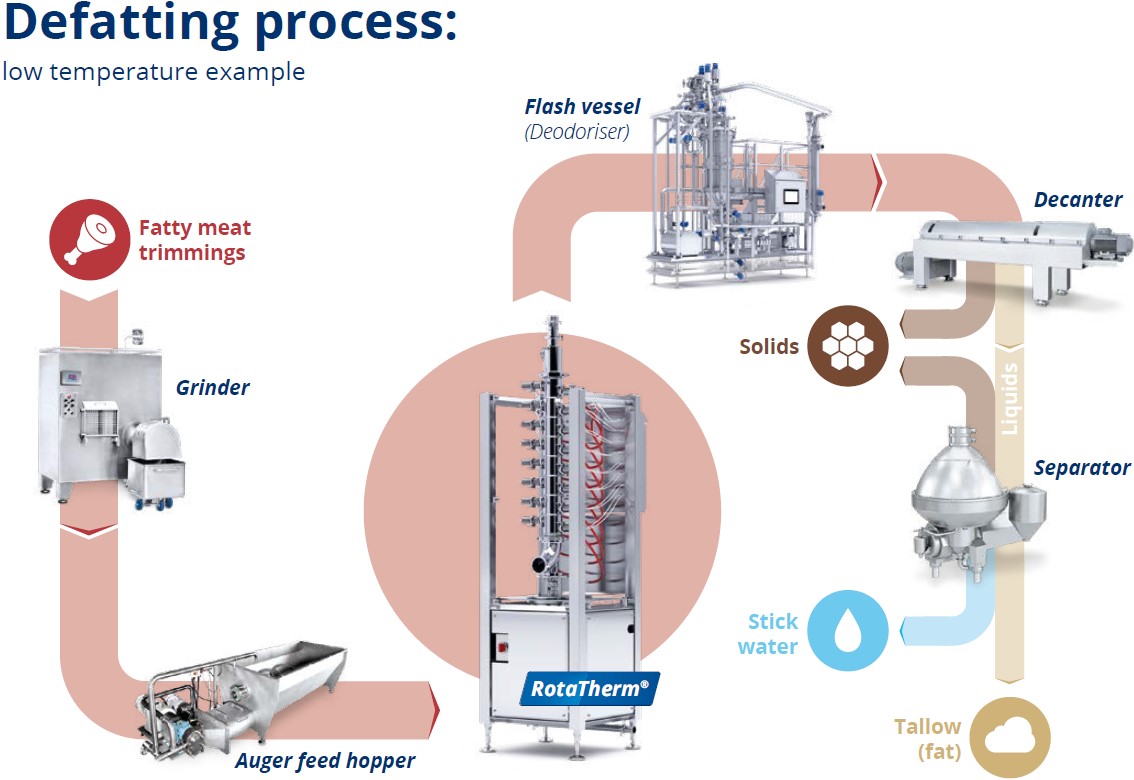

An example of the meat rendering equipment / defatting machines you might need is pictured here. We sell all elements of these systems, but our advantage is the cooker at the heart of it (note: our process doesn't cook the meat, it softens the fat). Only Natec has the RotaTherm® and the FreeTherm - two steam cookers that blow the competition out of the water. Why? Our machines use the world's best steam injection technology, and the RotaTherm can process up to 20 tons of meat per hour! Nobody else comes close.

Steam matters... In an instant, steam softens the fat, but an instant doesn't cook the meat. It's fast.

- RotaTherm® - The world's first and still leading continuous steam cooker, which can process up to 20 tons (44,000lb) per hour for 156 hours between fast CIP cleans (our smallest unit does up to 2 tons/h (4400lb)).

- FreeTherm - A multifunctional steam batch cooker that blends and cooks up to 4x 500kg (4x 1100lb) batches per hour (our smallest unit does up to 4x 50kg (4x 110lb) batches/h).

We make the cookers above and build full meat rendering production lines around them, achieving absolute maximum efficiency. We often integrate components, like separators, that are built by other world-leading providers.

Contact us to discuss your needs.

Defatting machines

The full meat rendering equipment / defatting machines process we have developed to be at the forefront of the field is this...

The full meat rendering equipment / defatting machines process we have developed to be at the forefront of the field is this...

- Grind the trimmings.

- Mix and feed by the Auger feed hopper.

- Soften the fat with a steam cooker.

- Hold and deodorise.

- Decant to separate the liquids and solids.

- Separate the tallow (fat), stick water and remaining soluble proteins using a separator (centrifuge).

- Recombine the solids and soluble proteins.

The tallow / fat our machines separate out is perfect for resale, giving you both higher value low fat meat and resaleable tallow.

Contact us today to find out more about our meat rendering equipment / defatting machines.