Benefits

Inline production

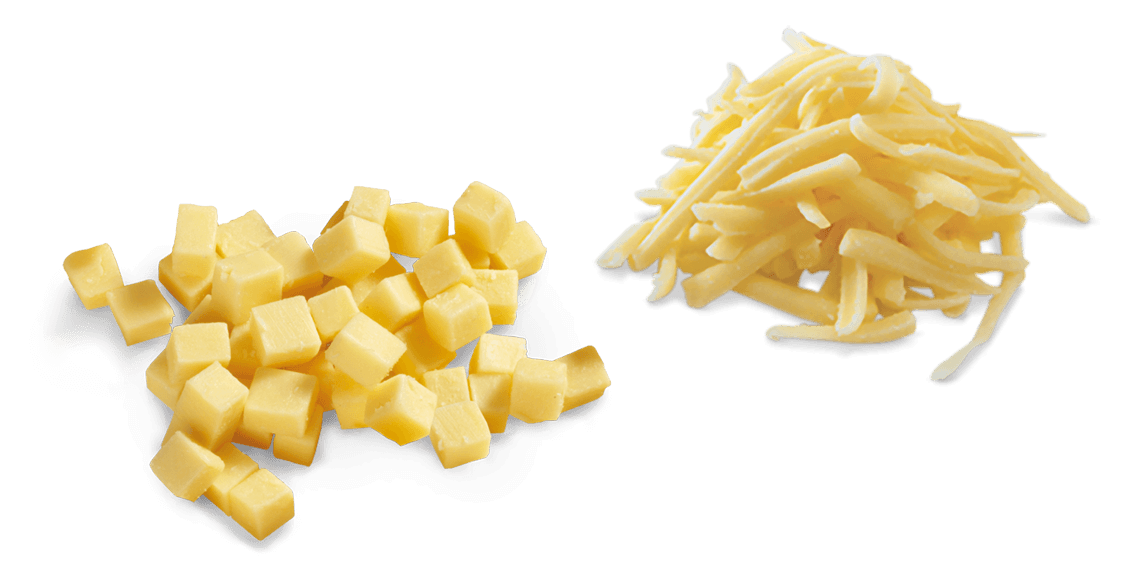

- Inline production of cubes and shreds (forming, cooling and cutting in one step)

HMI

- Different formats can be set at the HMI

Movable

- Movable on rollers

Cleaning

- Easy cleaning due to USDA design

No recontamination

- No risk of recontamination

Save money

- Low operating costs