Direct steam injection cooker (DSI)

Part of the Natec Network invented the world's first direct steam injection cooker (DSI) in 1988. It was called the RotaTherm®, and was protected, developed and enhanced over many years, without competition.

Part of the Natec Network invented the world's first direct steam injection cooker (DSI) in 1988. It was called the RotaTherm®, and was protected, developed and enhanced over many years, without competition.

RotaTherm®'s use of direct steam injection meant it could cook quicker and better than any other proper method on the planet. This allowed great volumes to be produced extremely efficiently. It became very popular, and we improved it.

While the early cookers could cook a whopping 2 tons per hour, today's Natec Network RotaTherm® can cook up to a extraordinary 20 tons per hour (for meat) for 156 hours between fast CIP cleans.

In more recent times, competitors have attempted to copy RotaTherm® and have produced their own flimsy imitation direct steam injection cookers (DSI). They do not have the expertise Natec does, and it shows. They haven't understood the importance of parts of the machine, and removed parts to make them cheaper. The result is things like food getting trapped and bacteria breeding.

In the meanwhile, Natec has continued to evolve the RotaTherm®, and developed 4 other direct steam injection cookers...

Today's Natec direct steam injection cooker (DSI)

- RotaTherm® - The world's first and still leading continuous steam cooker, which can cook up to 17 tons (37,500lb) per hour (20 tons for some meat applications) (our smallest unit does up to 2 tons/h (4400lb)).

- MicraTherm - An R&D scale steam batch cooker that replicates a RotaTherm®'s settings in 2-3kg (4-7lb) batches.

- FreeTherm - A multifunctional steam batch cooker that blends and cooks up to 4x 500kg (4x 1100lb) batches per hour (our smallest unit does up to 4x 50kg (4x 110lb) batches/h).

- ShearTherm - An emulsifier and steam batch cooker that does fine particle foods at up to 2,400L (634gal) per hour (our smallest unit does up to 600L/h (159 gal)).

- GPiCS - A Mozzarella and Pasta-Filata stretcher and continuous steam cooker that produces 6,000kg/h (13,227lb) with no bath cook water (smallest unit does up to 500kg/h (1100lb)).

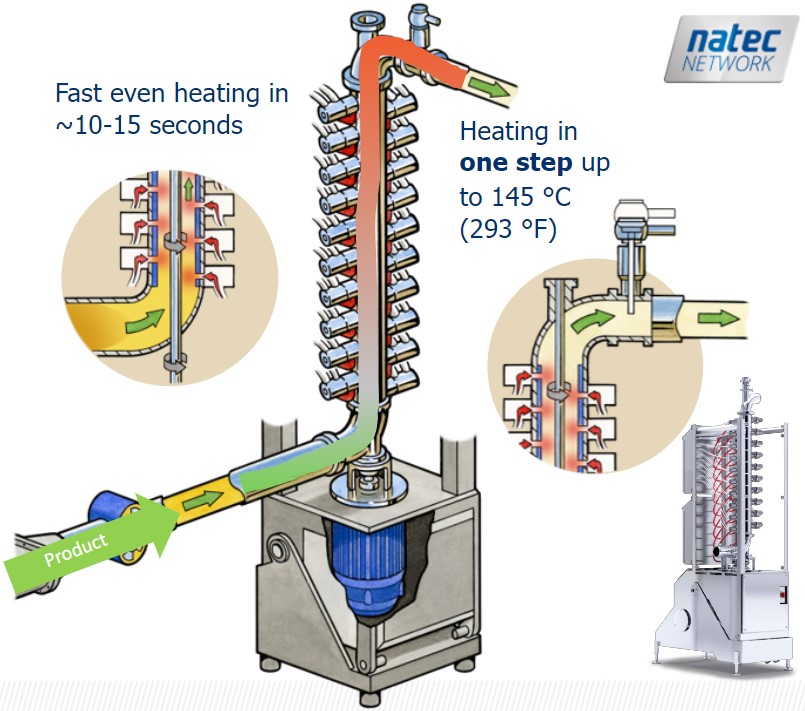

How DSI works

- Steam is the fastest way to cook. Steam comes from boiling water. That heat penetrates the food, heating it and moistening it at the same time.

- The steam is shot into the food using Natec's super-refined steam injectors.

- The nutrients and colours aren't burnt out. The process is fast and gentle, so it doesn't destroy the ingredients.

- The "Rota" bit of RotaTherm® means it contains rotors. These gently mix the food as it passes by the injectors, ensuring even cooking.

- The ingredients pass through a tube with rotors and injectors, so it continuously moves and cooks. You aren't limited to one batch at a time.

- All of that means a direct steam injection cooker provides extremely fast and nutritious cooking, at low cost, and very high capacity.

Their green (environmental) credentials are very strong too: they're very efficient, produce minimal waste, and don't take up much space in your factory's cooking bay. Their low running costs and high volumes give a fast return on investment.

Learn more about RotaTherm® now.