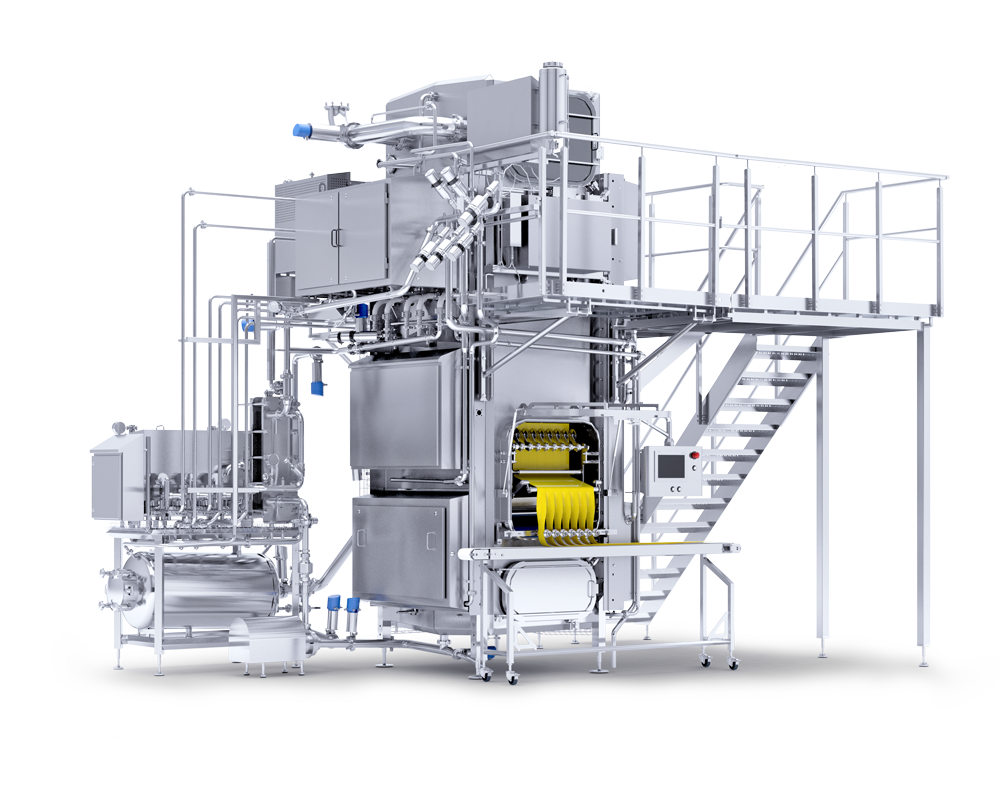

FreeSlice® 800

The Natec Network FreeSlice® system produces Slice-On-Slice (SOS) products. It is designed to produce Slice-On-Slice cheese as well as – with different applications – cubes, shreds and sticks made of processed cheese, analogue or hybrid cheese. An integrated laminar flow system makes safe and trouble-free production without any danger of recontamination possible. The FreeSlice® 800 can also be used for smaller production volumes or for R&D pilot purposes. It is designed as a ‘plug-in’ system with its integrated cooling unit, which does not need any cooling medium from customer side. The FreeSlice® system reduces the manpower required for operating and cleaning to a minimum and the vertical design of the belts guarantees high flexibility in slice thickness and formats.

Download datasheet Download benefits