Cheese processing equipment

Natec are the experts in cheese processing equipment. The Natec Network is a combination of Hochland-Natec and Gold Peg International. Hochland is Europe's (and possibly Earth's) largest processed cheese manufacturer. They established their own cheese machine manufacturing arm (Natec) in 1974. However, Gold Peg made cookers so much better than anyone in the world that Hochland bought several, and then bought the company

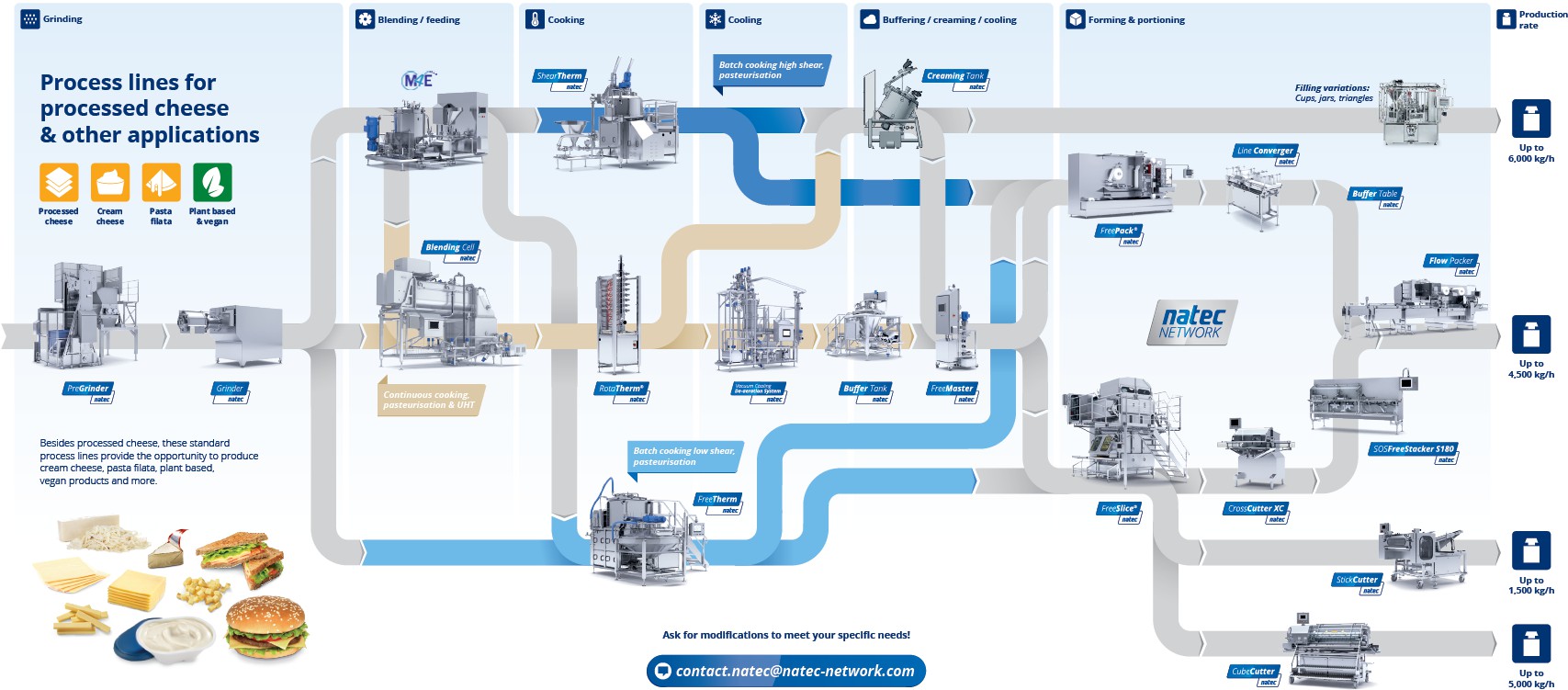

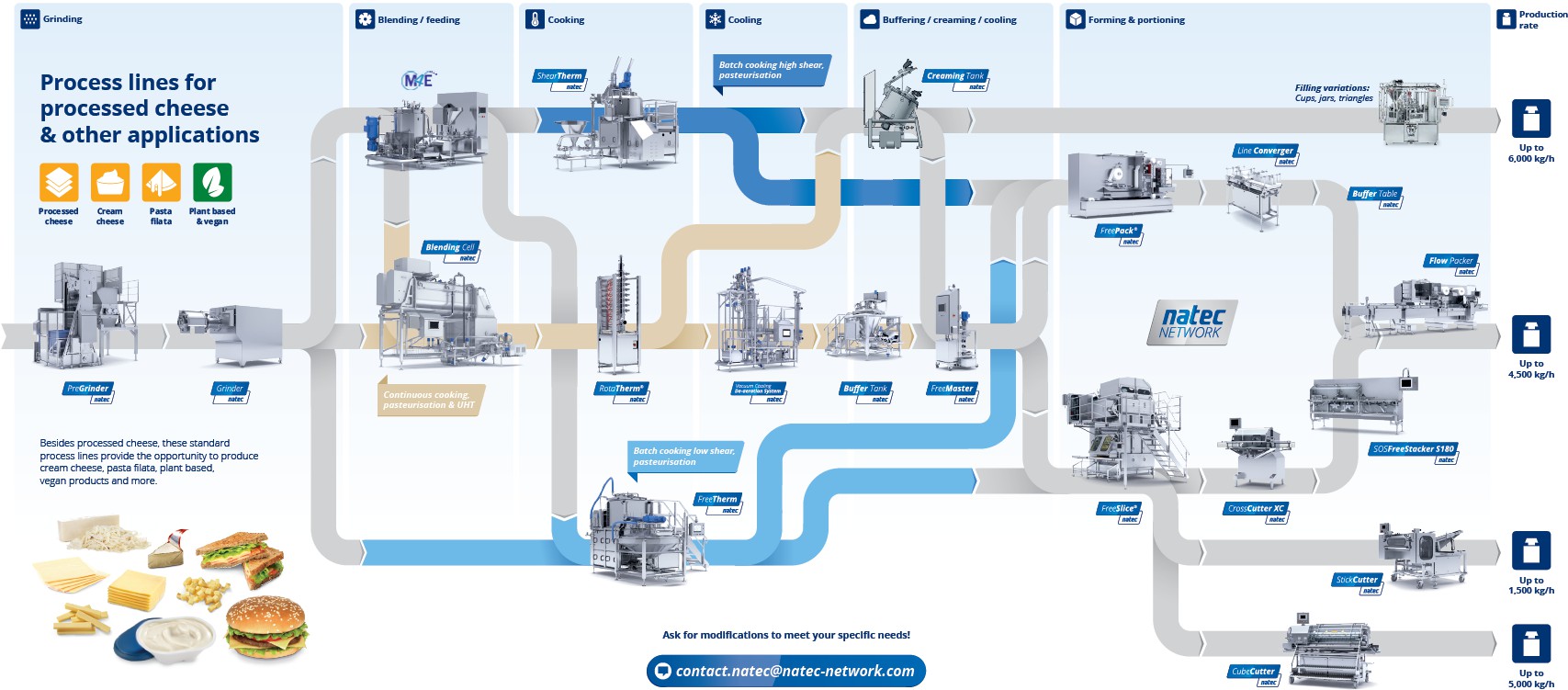

Today, the Natec Network builds cheese processing equipment of all types and sizes. We can provide grinders, conveyors, blenders, cookers (continuous & batch), filters, formers, cutters, wrapping machines, stackers, separators, and everything else you could need in a cheese production line.

Our cheese cookers can cook up to 17,000kg (17 tons, 37,500lb) per hour, continuously for up to 156 hours between fast Clean-In-Place cleans! No competitor comes close to that. At the other end of the scale, we have cookers that will do 8kg per hour.

Cheese machines

Natec's cheese machines are diverse, and tailored to your needs. Our cookers alone include:

- RotaTherm® - The world's first and still leading continuous steam cooker, which can cook up to 17 tons (37,500lb) per hour (our smallest unit does up to 2 tons/h (4400lb)).

- MicraTherm - An R&D scale steam batch cooker that replicates a RotaTherm's settings in 2-3kg (4-7lb) batches.

- FreeTherm - A multifunctional steam batch cooker that blends and cooks up to 4x 500kg (4x 1100lb) batches per hour (our smallest unit does up to 4x 50kg (4x 110lb) batches/h).

- ShearTherm - An emulsifier and steam batch cooker that does fine particle foods at up to 2,400L (634gal) per hour (our smallest unit does up to 600L/h (159 gal)).

- GPiCS - A Mozzarella and Pasta-Filata stretcher and continuous steam cooker that produces 6,000kg/h (13,227lb) with no bath cook water (smallest unit does up to 500kg/h (1100lb)).

Then we have:

- FreeSlice® - A cheese former / slicer that can slice up to 4,200 slices per minute (smallest unit does up to 360 slices/min).

- FreePack® - Can wrap up to 2,200 indivually wrapped slices (IWS) per minute, and uses 20% less wrap (smallest unit does up to 500 slices/min).

And then there's the grinders, conveyors, blenders, filters, formers, stackers, separators, and everything else.

You can see more line options in our Equipment Finder.

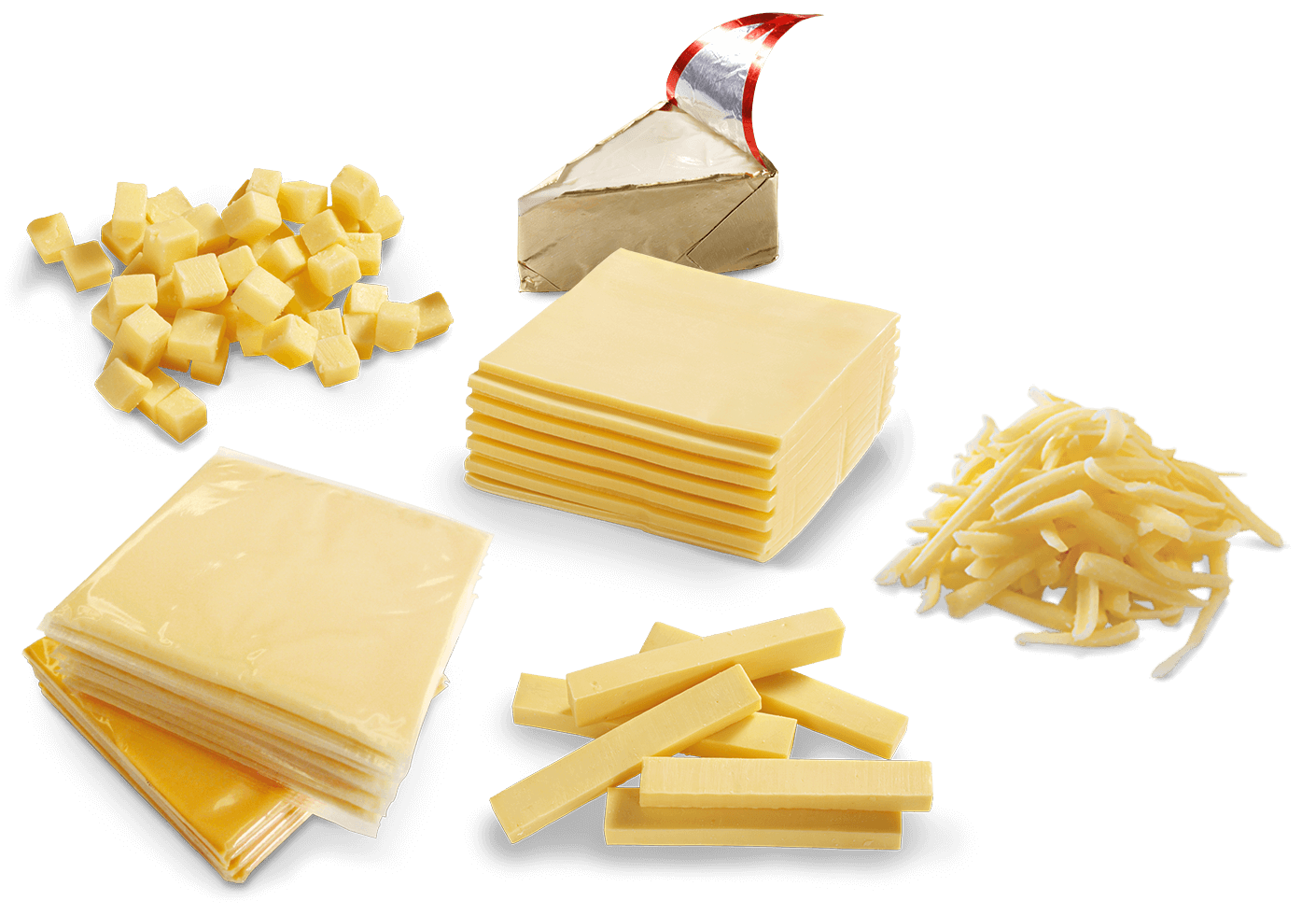

Processed Cheese:

Ideal products

for consumer markets

Processed cheese is the ideal product in the consumer market as it has a much longer shelf life than natural cheese and these products cover all the requirements around quality and hygiene. Production costs are kept low through complete ingredient usage while we help you to create an efficient line for your processed cheese machine needs.